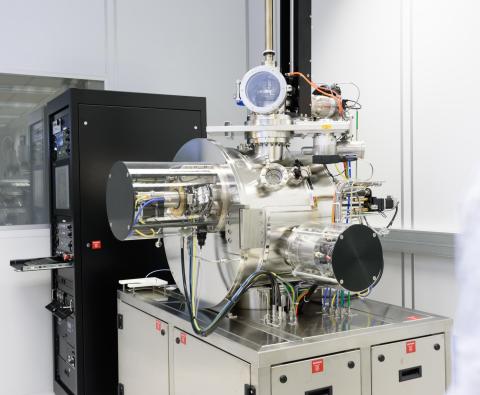

Ion Beam Sputtering System

High quality thin films & multilayers

Versatile ion beam sputtering (IBS) system for high-quality thin film deposition. Ideal for optics, photonics, and microelectronics research needing precise control of thickness, uniformity, and composition.

Contacts: Dr. Olga Girshevitz, olga.girshevitz@biu.ac.il, Mr. Mark Oksman, mark.oksman@biu.ac.il

Model: Intelvac Nano Quest

Manufacture: Intlvac

Description:

Ion Beam Sputtering (IBS) with Ion Assist/Etch is a high-precision thin film deposition technique designed for applications requiring exceptional film quality, such as advanced optical and magnetic coatings. The process operates at low pressure (~10⁻⁴ Torr), allowing sputtered atoms to retain higher kinetic energy due to minimal scattering, which results in:

- Dense, smooth, and pinhole-free films

- Excellent step coverage, even at small thicknesses and on high-aspect-ratio features

- Improved film adhesion and microstructure control through optional ion assist or etching

- This method is ideal for fabricating high-performance multilayer structures where uniformity, surface quality, and reproducibility are critical.

Specifications:

- 4 targets and ION ASSIST/Etch source

- Low pressure sputter deposition (10-4 Torr)

- High quality, smooth, pin hole free films

- Enhanced adhesion and micro-structure control

- Independent control of ion beam parameters allows user to engineer film with desired properties

Materials that may be deposited

- Oxides: SiO2, Al2O3, HfO2, Ta2O5, TiO2

- Metals: Al, Ag, Ta, Ti, Nb

- Others: Ge, Si, Si p-type, Si n-type, Permalloy, ITO, FTO, MOL4, SiC

Last Updated Date : 16/11/2025